ISO9001 Certified Professional Manufacturer & Supplier of Optics

+86-0431-87911611 admin@ytoptics.com

Contact us

-

Email: admin@ytoptics.com

Email: admin@ytoptics.com

-

Tel:86-0431-87911611

Tel:86-0431-87911611

-

Add: 2# Automotive Innovation

Add: 2# Automotive Innovation

Jilin Province, China

Why choose broadband anti-reflective coating(BBAR)?

In the field of modern optical technology, every fraction of lost light energy can become a bottleneck in system performance. When traditional single-layer anti-reflective coatings fail to meet the demands of multispectral, wide-angle, and high-precision optics, broadband anti-reflective coatings (BBAR) emerge as a critical technological solution for engineers and designers.

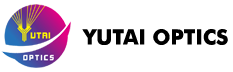

Broadband Anti-Reflection Coatings: Wider Spectrum, Higher Performance

Through a precisely engineered multilayer structure, broadband anti-reflection coatings deliver exceptional anti-reflection performance across a broader spectral range. Compared to traditional anti-reflective coatings optimized for single wavelengths, our BBAR coatings consistently maintain single-surface reflectance below 0.5% across the entire visible spectrum (400-700nm) and even extend into broader infrared or ultraviolet bands. In specific wavelength bands, reflectance can be reduced to below 0.2%.

What core advantages does this broadband high-transmission characteristic deliver?

Comprehensively enhances system light transmission efficiency—in complex optical systems, approximately 4% reflection loss at each air-glass interface accumulates exponentially. By adopting our broadband anti-reflective coating, the overall transmission of multi-element lens assemblies can be improved by 20%-40%, significantly boosting signal strength.

Improved imaging quality—Substantially reduces ghosting and stray light, boosting image contrast by over 30% to deliver purer, more authentic visual performance for high-end imaging applications

Expanded design flexibility—Optical designers gain greater freedom to incorporate additional elements for aberration correction without excessive concern over transmission loss.

What are the application areas of broadband anti-reflective coatings?

As an advanced optical thin-film technology, broadband anti-reflective coatings have become indispensable key components in numerous high-end optical applications due to their exceptional performance in significantly enhancing transmittance across a broad spectral range while suppressing stray light.

1. Precision Imaging and Detection Applications

In high-end microscopes, broadband anti-reflective coatings effectively boost transmission from ultraviolet to near-infrared wavelengths, minimize fluorescence signal loss, and significantly enhance imaging signal-to-noise ratio and contrast. Within semiconductor inspection equipment optical systems, multi-element lens assemblies featuring customized BBAR coatings achieve ultra-low reflectance (<0.5%) across deep ultraviolet to visible light, ensuring precision in wafer defect detection.

2. Laser and Optoelectronic Systems

In high-power laser systems, optical components face challenges beyond high transmittance requirements—they must also withstand high energy densities. Our BBAR coating employs specialized material design and processes to achieve >99.8% transmittance at common laser wavelengths like 1064nm and 532nm, while maintaining a high laser damage threshold (LIDT) for long-term system stability. WDM modules in fiber optic communications also benefit from broadband anti-reflection technology, reducing insertion loss and increasing channel capacity.

3. Consumer Electronics and Display Technology

Smartphone multi-lens systems exemplify BBAR technology's widespread adoption. Coating each lens element with broadband anti-reflective films on both sides elevates the total light transmission of a seven-element lens assembly from under 50% to over 90%, directly improving low-light photography performance. BBAR-treated optical combiners and display lenses in AR/VR devices effectively suppress internal reflection ghosting, enhancing the clarity and realism of immersive experiences.

4. Aerospace and Defense Optics

Multispectral cameras for remote sensing satellites must operate across an extremely broad range of 400-2500nm. Our custom BBAR coatings can be optimized for specific wavelength combinations, ensuring signal consistency across all channels. Infrared night vision and thermal imaging systems leverage BBAR technology to enhance transmission in the 8-14μm band, boosting low-light detection capabilities. BBAR-treated optical windows for lidar systems minimize signal loss from echoes, improving detection accuracy and range.

5. New Energy and Scientific Research Equipment

In the photovoltaic industry, BBAR coatings applied to Fresnel lenses in Concentrated Photovoltaic (CPV) systems significantly improve energy collection efficiency across the ultraviolet-visible-near-infrared spectrum. Optical components for large scientific facilities like synchrotron radiation beamlines and space telescopes rely on ultra-low reflectivity coatings across an extremely broad band (from X-rays to far-infrared) to obtain the purest experimental data.

What optical coatings does Yutai Optics recommend?

Selecting the right BBAR solution means establishing a foundation of superior performance and stable reliability for your optical system.

Yutai Optics' optical coating facility not only allows us to produce large numbers of our catalog optics in house but also expands our ability to manufacture custom-coated optics to suit a variety of customer needs. Yutai's BBAR coatings provide good performance for angles of incidence between 0° and 30° and a numerical aperture (NA) of 0.5.

Here we recommend Yutai's coating ability.

AR coating,BBAR coating, DLC coating, AF/AS coating, Hydrophobic Coating, ITO/FTO coating.

Some coatings can be combined, such as:

AR+AF/AS coating, AR+DLC coating, ITO/FTO+AR coating.

Comprehensively enhances system light transmission efficiency—in complex optical systems, approximately 4% reflection loss at each air-glass interface accumulates exponentially. By adopting our broadband anti-reflective coating, the overall transmission of multi-element lens assemblies can be improved by 20%-40%, significantly boosting signal strength.

Improved imaging quality—Substantially reduces ghosting and stray light, boosting image contrast by over 30% to deliver purer, more authentic visual performance for high-end imaging applications

Expanded design flexibility—Optical designers gain greater freedom to incorporate additional elements for aberration correction without excessive concern over transmission loss.

What are the application areas of broadband anti-reflective coatings?

As an advanced optical thin-film technology, broadband anti-reflective coatings have become indispensable key components in numerous high-end optical applications due to their exceptional performance in significantly enhancing transmittance across a broad spectral range while suppressing stray light.

1. Precision Imaging and Detection Applications

In high-end microscopes, broadband anti-reflective coatings effectively boost transmission from ultraviolet to near-infrared wavelengths, minimize fluorescence signal loss, and significantly enhance imaging signal-to-noise ratio and contrast. Within semiconductor inspection equipment optical systems, multi-element lens assemblies featuring customized BBAR coatings achieve ultra-low reflectance (<0.5%) across deep ultraviolet to visible light, ensuring precision in wafer defect detection.

2. Laser and Optoelectronic Systems

In high-power laser systems, optical components face challenges beyond high transmittance requirements—they must also withstand high energy densities. Our BBAR coating employs specialized material design and processes to achieve >99.8% transmittance at common laser wavelengths like 1064nm and 532nm, while maintaining a high laser damage threshold (LIDT) for long-term system stability. WDM modules in fiber optic communications also benefit from broadband anti-reflection technology, reducing insertion loss and increasing channel capacity.

3. Consumer Electronics and Display Technology

Smartphone multi-lens systems exemplify BBAR technology's widespread adoption. Coating each lens element with broadband anti-reflective films on both sides elevates the total light transmission of a seven-element lens assembly from under 50% to over 90%, directly improving low-light photography performance. BBAR-treated optical combiners and display lenses in AR/VR devices effectively suppress internal reflection ghosting, enhancing the clarity and realism of immersive experiences.

4. Aerospace and Defense Optics

Multispectral cameras for remote sensing satellites must operate across an extremely broad range of 400-2500nm. Our custom BBAR coatings can be optimized for specific wavelength combinations, ensuring signal consistency across all channels. Infrared night vision and thermal imaging systems leverage BBAR technology to enhance transmission in the 8-14μm band, boosting low-light detection capabilities. BBAR-treated optical windows for lidar systems minimize signal loss from echoes, improving detection accuracy and range.

5. New Energy and Scientific Research Equipment

In the photovoltaic industry, BBAR coatings applied to Fresnel lenses in Concentrated Photovoltaic (CPV) systems significantly improve energy collection efficiency across the ultraviolet-visible-near-infrared spectrum. Optical components for large scientific facilities like synchrotron radiation beamlines and space telescopes rely on ultra-low reflectivity coatings across an extremely broad band (from X-rays to far-infrared) to obtain the purest experimental data.

What optical coatings does Yutai Optics recommend?

Selecting the right BBAR solution means establishing a foundation of superior performance and stable reliability for your optical system.

Yutai Optics' optical coating facility not only allows us to produce large numbers of our catalog optics in house but also expands our ability to manufacture custom-coated optics to suit a variety of customer needs. Yutai's BBAR coatings provide good performance for angles of incidence between 0° and 30° and a numerical aperture (NA) of 0.5.

Here we recommend Yutai's coating ability.

AR coating,BBAR coating, DLC coating, AF/AS coating, Hydrophobic Coating, ITO/FTO coating.

Some coatings can be combined, such as:

AR+AF/AS coating, AR+DLC coating, ITO/FTO+AR coating.

NEXT : Principles and Applications of Visible High-Transmission Glass

TALK TO US 86-0431-87911611

86-0431-87911611

Call us now!

86-0431-87911611

86-0431-87911611Call us now!

ONLINE CHAT

2433808388

2433808388